For a cannabis brand or distribution company, your products are the heart of your organization. As such, effectively managing inventory stock levels is critical not only to the success of your end-to-end supply chain but your business as a whole. Inadequate and insufficient inventory management principles result in internal operational inefficiencies, inventory overages or shortages, and ultimately discounted or lost sales. As a new cannabis business, each and every component of inventory impacts your COGS and bottom line, and as your business begins to scale, proper management of your inventory will become even more critical. This is why taking the necessary steps to establish sound inventory management practices early in your company’s evolution will help optimize your internal operations and be crucial to your overall success. To this end, investing in a software platform designed specifically to manage cannabis inventory will help you dodge some supply chain bullets that could otherwise kill your business, is the best first step. Understanding and implementing inventory management strategies to address five common reasons for inaccurate stock levels will be vital to your supply chain success.

- Theft

○ Issue: Research shows that approximately 75% of employees have stolen from an employer at least once. While the severity of the theft will vary, the result is the same; lost revenue, inaccurate inventory counts, and potential issues fulfilling customer orders. With the high valued products, large amounts of cash transactions, and the thriving black market in today’s cannabis industry, the opportunity for inside theft grows exponentially. While much of the focus tends to be on loss prevention within a retail setting, cultivators, processors, and distributors share these same challenges. As your organization begins to grow in headcount and your inventory volume increases, making time for physical inventory counts and not knowing what is happening day-to-day with inventory creates an even greater opportunity and risk for internal theft.

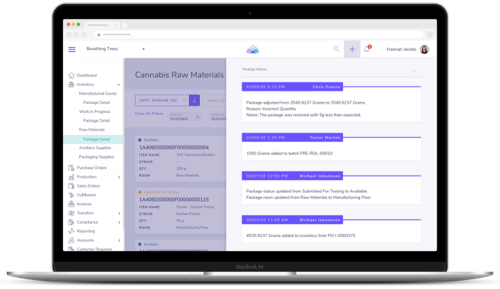

○ Resolutions: Having a digital record of every inventory-related transaction is the first critical step to identifying and researching potential theft issues. Moving your business from paper to a software platform in some cases can be a significant transition for your team; however, the insights are telling. We have seen some operators move from paper (with manual METRC data entry) to a single real-time inventory and METRC integrated platform surprisingly reveals internal cases of “sticky fingers.” Not only should your software platform manage all types of inventory (cannabis and non-cannabis) to the smallest individual unit of measure, but it should include robust audit trails. Roshi’s background in FDA/GMP compliant software brings GMP-compliant data integrity to your cannabis operation. GMP relevant data (additions, changes, and deletions) are included in a viewable audit log with a date/time stamp with the user that performed the activity.

- Lack of Automation and Human Error

○ Issue: Data entry. It’s a necessary, integral, yet manual and often riddled with errors. We’ve all experienced that instance when you realize you have typed an incorrect number, entered a number twice, or skipped a line altogether, making whatever it was that you were calculating wildly inaccurate. These errors become even more frequent when your internal processes call for 1) real-time paper recording from one person and data transcription into systems hours later by a completely different person, and 2) double data entry into multiple systems. Using tools such as Excel to track and manage your inventory is not only prone to human error and inventory inaccuracies, but it’s slow and cost/resource intensive too!

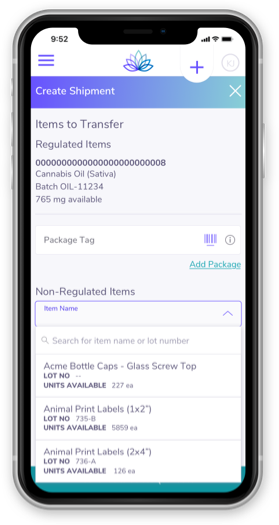

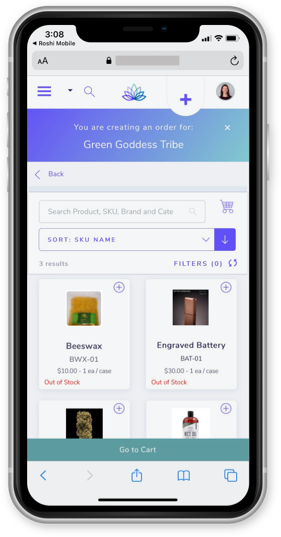

○ Resolutions: Optimizing the processes for data capture, reducing the amount of data entry required, and streamlining the data entry experiences are the key drivers in reducing human error. By implementing a software program that distributes data entry to those performing activities, you not only increase data quality but create a more efficient operation along the way. Product design research confirms that user interface design directly impacts data quality, and Roshi’s mobile app takes this research to heart. With a modern interface for today’s cannabis workforce and capabilities to scan barcodes, Roshi makes data entry clean, clear, and simple for end-users. Additionally, deploying tools such as Roshi that perform automatic calculations, default to configured settings, and integrate with other systems to limit the amount of data entry required altogether.

- Inconsistent Cycle Counts

○ Issue: Not performing regular cycle counts and inventory reconciliation is a common cause of inaccurate stock levels across cannabis operators. Finding the time when inventory is not moving can be difficult, and completing a 100% bottoms-up cycle count can seem daunting, particularly for larger organizations with many SKUs. And, even when operators do find the time to perform cycle counts, their practices are insufficient, all for the sake of wanting to save time. For example, printing out a sheet of inventory items and the related quantities in your system is fast and efficient but rarely results in making the inventory reconciliation required. As you can imagine, during these unblinded cycle counts, employees may find it tempting just to confirm the number is correct. Additionally, these paper processes do not adequately include supervisors in the oversight process, ultimately leading to unforeseen inventory emergencies down the line.

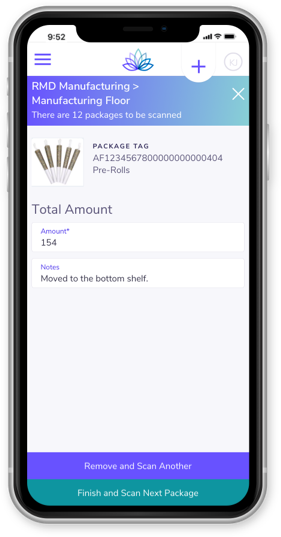

○ Resolution: Best practices indicate that blinded or partially blinded cycle counts lead to more accurate inventory reconciliation. That is because if the employee performing the counts doesn’t know the expected quantity, you’ll be more likely to catch errors. In Roshi’s cycle count module, users are blinded to package quantities and simply scan packages and enter their quantities as counted. This enables your cycle counts not only to be blinded but double-blinded assigning the cycle count responsibility to any staff member regardless of their warehouse/inventory knowledge. The oversight (cycle count review and reconciliation) comes from a managerial staff with the permissions to approve any required stock adjustments resulting from a cycle count. This oversight not only solves loss prevention issues during cycle counts but also puts the ownness on managerial level staff to make changes that have direct financial impacts on your business.

- Wrong Room Storage

○ Issue: Have you found yourself searching around your facility looking for an inventory item you know you have? Don’t worry; you aren’t the only one.

Not keeping up to date with the movement of inventory between rooms or not tracking and managing inventory by room at all is another area where stock can easily go unaccounted. Keeping your like items (finished goods, raw materials, quarantined, etc.) together is the key to efficient inventory storage. Not only is it a compliance issue to not know where your inventory is, but it leads to “missing” inventory. Think of it like a pair of socks. How many unmatched socks do we end up with every year? It’s not that they are physically gone; they are just missing from the same place as the other sock. So, while we may have two socks, they are not in a useable state until they are together.

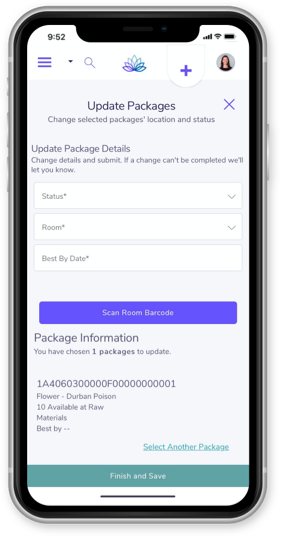

○ Resolution: Be prepared to tell auditors exactly where every piece of inventory is within your facility. With Roshi’s tracking capabilities, gain the trust and confidence of auditors by managing and tracking your inventory by physical location and/or room. Whether you decide to track your inventory by room, shelf, or bin, scan barcode locations and items to move inventory from one location to another seamlessly.

- Your Inventory Isn’t Real-Time

○ Issue: When paper is king and data entry from the day happens after hours, your inventory can never be truly real-time. This, in conjunction with the speed of new batches, extraction processes, or sales orders, makes it too difficult to keep track of available inventory, inventory allocated to orders, and what’s out of stock. Any value gained from order management systems and processes is lost without connected real-time inventory to deliver on your customer commitments. Both sales teams and customer trust is lost. In any fast-paced business, anything other than real-time is too late.

○ Resolution: A centralized inventory management system ensures that all parts of your organization are on the same page. Each department can see what one another is doing, and the inventory counts are always up to date. Roshi’s real-time sales inventory module offers sales teams an e-commerce type experience with advanced logic for multiple uses vying for the same inventory simultaneously. Only sell what’s in stock, never overcommit, and build customer trust.

Adopting inventory management best practices in your organization will pay dividends in ways you have not intended. Accurate inventory levels can optimize and make your processes more efficient, but the big business impacts are far-reaching. With accurate inventory management, you can prevent inventory loss and redeploy capital, produce robust financial reports on inventory value in your organization, and ultimately demonstrate the rigor around your inventory practices. As with any good habit, starting as early as possible will improve accuracy, and more quickly result in money saved and peace of mind. Click below for a demonstration of how Roshi can help you stay on top of your inventory.